The DX8210 is Datalogic’s new high-performance laser bar code reader purpose-built to offer top reading performance combined and ease of use to End User and System Integrators specialized in the Transport and Logistics market.

Thanks to its unique design, Datalogic DX8210 offers an ALL-IN-ONE solution for omnidirectional reading stations. This single device is capable of reading codes at any orientation on the conveyor. With the benefits of state-of-the-art technology and innovative optic design, DX8210 can cover a wide conveyor and large depth of field to satisfy demanding applications. A high scan rate (2000 scans/sec) allows DX8210 to work perfectly on high speed conveyors for mass production.

The innovative DST (Digital Signal Technology) drastically increases optic performance even in cases where code quality is unpredictable. DST offers stable and constant performance under any working conditions to ensure logistic operators maintain timely deliveries.

Multi-headed tunnel configurations are perfectly managed with EBC (Ethernet Bus Connection), allowing high speed data transmission and real time signal synchronization inside the system. EBC allows redundant configuration, assuring no system deadlock in case of component failure.

Ease of use, automatic setup and system diagnostics are perfectly satisfied thanks to e-GENIUS, the web browser configuration tool that allows you to access the system with a standard web-browser program with no need for specific configuration software.

Scanner Device only, additional accessories are required.

936300004

Contact us for stock availability

936300003

Contact us for stock availability

Contact for order requests

936300001

Contact us for stock availability

Contact for order requests

Required, some fixed scanners have communication cables molded into the housing to connect to the connection box, output cables may still be required. Please refer to topography diagram in Reference manual for more information.

93A050060

7 In stock

Contact for order requests

93A050059

Limited stock available

Contact for order requests

93A051347

Contact us for stock availability

Contact for order requests

93A051346

Contact us for stock availability

Contact for order requests

93A050058

Contact us for stock availability

Contact for order requests

Required on all fixed mount scanning unless Quicklink Series connections are used. Please specify additional outputs if required and adapters.

935750003

Contact us for stock availability

Contact for order requests

935750002

Contact us for stock availability

935750001

Contact us for stock availability

93A301077

Contact us for stock availability

Contact for order requests

93A301087

Contact us for stock availability

Contact for order requests

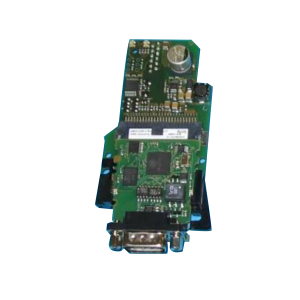

Optional (only required on certain models), only works with CBX500 & CBX800 connection boxes.

93ACC1852

Contact us for stock availability

93ACC1851

Contact us for stock availability

Contact for order requests

93ACC1849

Contact us for stock availability

93ACC1848

Contact us for stock availability

Contact for order requests

93ACC1845

Contact us for stock availability

93ACC1840

Contact us for stock availability

Contact for order requests

93ACC1816

Contact us for stock availability

Contact for order requests

93ACC1815

Contact us for stock availability

93ACC1814

Contact us for stock availability

93ACC1813

Contact us for stock availability

Contact for order requests

93ACC1812

Contact us for stock availability

Contact for order requests

93ACC1811

Contact us for stock availability

Contact for order requests

93ACC1810

Contact us for stock availability

Contact for order requests

93ACC1809

Contact us for stock availability

Contact for order requests

93ACC0113

Contact us for stock availability

Contact for order requests

93ACC1808

Contact us for stock availability

Contact for order requests

Additional Accessory – only required for certain cable sets.

Optional on request.

(Optional) WebSentinel Plus is a very advanced monitor and information collector, a supervisory software solution for monitoring operational activities of reading devices through a single web browser-based interface. It collects data from scan points through an Ethernet TCP/IP network, and presents the information flow as visual onscreen information. It also stores this information in a database and, periodically or on demand, produces performance, diagnostic, and tracking reports.

93A101026

Contact us for stock availability

93A101025

Contact us for stock availability

93A101024

Contact us for stock availability

93A101023

Contact us for stock availability

93A101022

Contact us for stock availability

93A101021

Contact us for stock availability