AREX401, in the same compact, rugged, and lightweight scan-head design, now delivers an incredible average power of 100W expanding by far the marking capabilities on automotive and aerospace components in terms of marking speed and engraving depth, to ensure reliable traceability on components that are exposed to high stress or wear in harsh environments or that are subject to aggressive post processing and finishing.

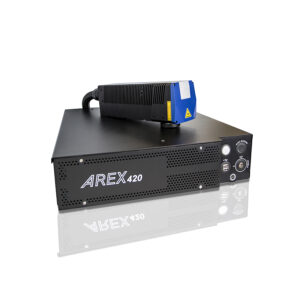

Datalogic is pleased to announce that a new product is joining the AREX400 family of High Performance fiber laser markers: the AREX401.

AREX401, in the same compact, rugged, and lightweight scan-head design, now delivers an incredible average power of 100W expanding by far the marking capabilities on automotive and aerospace components in terms of marking speed and engraving depth, to ensure reliable traceability on components that are exposed to high stress or wear in harsh environments or that are subject to aggressive post processing and finishing.

High performance f-theta lenses

Two new f-theta lenses have been specifically developed for the new AREX401, the new F=160 M60 and the new F=254 M60. These new, compact, and performing medium-sized f-theta lenses provide low optical losses, high resolution, wide marking areas with full protection from dust, oil, and water.

In addition, a field replaceable, protective glass guarantee provides quick and easy cleaning with no production stops, ensuring high protection and a long lifetime of these sophisticated and performing components. The new M60 f-theta lenses do not need a mounting adapter.

Simplified Integration

AREX401 now offers an improved Digital IO interface, totally backwards compatible, that simplify integration into automatic production line and PLC controlled environments.

Historically, PNP outputs (sinking 24 VDC inputs) are generally more diffused in North America and Europe, whereas the NPN solution (sourcing 24 VDC inputs) is typically more common in Asia. Most U.S. and EU technicians often find PNP sensors easier to understand because the device produces a high-level voltage signal when the output is active. Most of the time integrators need to be ready to support both topologies withing the same automation architecture.

To better match PLCs input configuration, speeding up wiring and connections, AREX401 Digital Outputs are now configurable NPN or PNP.

Enhanced Safe Laser Off (eSLO)

The new AREX401 now embeds a TÜV certified, improved version of Datalogic’s Safe Laser Off (SLO) circuit, that is now fully electronic, faster, and non-wearing and easier to integrate.

The new SLO version now allows faster switching time (complete cycle ONOFFON in 0.6 seconds) and ensures virtually an unlimited number of operations for the entire lifetime of the system.

A safety circuit based on electro-mechanical devices offers a limited number of operations, that depending on the real production run, may limit the achievement of higher safety Performance Levels and may need periodic replacement or refurbishment.

The AREX401’s enhanced Safe Laser Off (eSLO) circuit is completely solid state, without parts subject to wear, and offers unmatched performances in terms of reliability (PFHd Probability of Dangerous Failure). Even in the most demanding applications with the highest production rate and number of commutations, the reliability of the new eSLO greatly exceeds the entire machine Mission Time (20 years).

Going Deeper, Faster

The 100W fiber laser source allows users to unleash the performance of the AREX400 family, in terms of high-speed marking, up to 620 CPS (characters per second) with high quality, and in terms of deep engraving with a capability of removing up to of 200 mm of aluminum per minute (MRR: Material Removal Rate).

All the time a traceability code needs to survive a high level of abrasion, wear or stress, laser deep engraving is the solution to guarantee robust traceability.

AREX401 has been specifically developed to provide clear and durable deep markings that ensure perfect readability even in the toughest conditions without compromising process time.

Reliable Solution For Marking Before Post-Treatments

Several components and parts used in the manufacturing industry are subjected to severe stress, wear and exposed to adverse environmental conditions and corrosion.

The Automotive industry, in order to achieve better wear and corrosion resistance together with a good appearance, relies more and more on the e-coating process, like Cataphoresis Black Epoxy (KTL), to ensure long-term integrity of the vehicle structure. These important protective coatings may interfere with the need of extended traceability along the entire production line, from the forgery to the final test and delivery of the parts.

The new AREX401 provides an effective and efficient solution to create engraved or embossed marks that maintain high contrast and readability even after post-process like powder coating, e-coating or galvanizing treatments, without compromising the performances of the protective coating and the need of a complete traceability process.

Arex400, The Complete Family

With the new AREX401, the AREX400 family is today one the most complete family of industrial fiber laser markers on the market covering any application from 10W to 100W, completely maintenance free.

High Output Power: 100W

Strong and reliable

NPN/ PNP Configuration Outputs

AREX401 introduces a new IOs interface with configurable NPN /PNP outputs

New Software Features

The new release fo Lighter Usite introduces new features designed to improve engravig capabilities of the new AREX401:

Robot Ready

New F-Theta Lenses

AUTOMOTIVE

Main Application

Key Success Factors

Selling Arguments

Laser Marking in the casting industry

In modern industries, traceability has been extensively implemented along the entire production process to ensure tracking and tracing of each components or sub-systems.

In the casting industry the need of complete traceability down to single item serialization is strongly affected by invasive post process like shot-blasting and shot-peening.

Thanks to the combination of high power and specific code optimization the new AREX401 can provide reliable serialization on die casted components that guarantee reliable traceability and short cycle times.

Going deeper with laser

Sometimes laser etching or laser annealing is not enough. Deep marking s widely required on components that are subject to tear and wear.

AREX401 is the Datalogic laser marking solution for efficient deep engraving with a Material Removal Rate (MRR) up to 200 mm3/min on die casted aluminum alloys

The AREX401’s high power provides efficient deep engraving without compromising process time, going deeper, faster.

VIN MARKING

In automotive industry the Vehicle Identification Number (VIN) is a unique code assigned to every motor vehicle when it’s manufactured.

The VIN is a 17-character string of letters and numbers that provides a specific piece of information about the vehicle, including the year, country, and factory of manufacture.

In recent years, laser markers replaced dot percussion systems providing better performances in terms of reliability and flexibility.

Traceability on Coated Components

Corrosion resistant coatings, like cataphoresis or KTL/e coating, are widely used to provide durable, long-lasting protection to components exposed to harsh environment.

The new AREX401 provides an effective and efficient solution to create engraved or embossed marks that maintain high contrast and readability even after post-process like powder coating, e-coating or galvanizing treatments, without compromising the performances of the protective coating and the need of a complete traceability process.

Marking on the move

Thanks to the compact and lightweight design of the scanning head, AREX400 laser markers can be easily integrated on a small payload robot arm to boost process flexibility and reach any position on massive or hard to manipulate components. The robotic-grade conduit ensures long life, simple and cost-effective integration on the move.

Whenever your application is static on the dynamic, AREX400 is the laser marking solution for your traceability needs.

N/A

Laser Only, please select additional accessories if required.

985180125

Contact us for stock availability

985180124

Contact us for stock availability

985180105

Contact us for stock availability

985180104

Contact us for stock availability

985180103

Contact us for stock availability

Laser Only, please select additional accessories if required.

985180117

Contact us for stock availability

985180116

Contact us for stock availability

985180114

Contact us for stock availability

985180113

Contact us for stock availability

985180112

Contact us for stock availability

985180111

Contact us for stock availability

985180110

Contact us for stock availability

985180108

Contact us for stock availability

Contact for order requests

985180107

Contact us for stock availability

985180106

Contact us for stock availability

Laser Only, please select additional accessories if required.

985180120

Contact us for stock availability

985180119

Contact us for stock availability

985180118

Contact us for stock availability

Laser Only, please select additional accessories if required.

985180123

Contact us for stock availability

985180122

Contact us for stock availability

Contact for order requests

985180121

Contact us for stock availability

Contact for order requests

Please specify cable type if required (additional accessory).

Optional Accessories.

Additional Accessory – only required for certain cable sets.

Optional on request.