The Datalogic Matrix 220 XAI imager is the most compact image-based bar code reader for top performance with the highest flexibility. It is the ideal image reader for Electronics, Automotive and Packaging.

AI-Powered. Industry-Leading. Future-Ready.

The Matrix 220 XAI imager is the most compact image based bar code reader for top performance with the highest flexibility. It is the ideal image reader for Electronics, Automotive and Packaging.

The new Matrix 220 XAI models take performance to an unprecedented level, successfully handling even the most challenging DPM codes. Thanks to the combination of the fastest Auto Setup routine, additional processing power, optimized software multithreading, and an innovative AI-based approach, the decoding process is accelerated by

up to 2.5 times, ensuring reliable results even with variable DPM codes on any material, thus elevating efficiency in traceability through DPM codes.

The Matrix 220 XAI offers in a single model the polarized and diffused light options resulting in optimal illumination on any type of surface. The lights, red and blue, allow models to solve a huge variety of applications with the best perfomance.

The Matrix 220 XAI imager has the best ease of use because of the green and red spot lights, the X-Press™ button, the intuitive HMI and the DL.CODE™ configuration software, which has been improved with the Automatic Setup mode for a quick and easy code reading. ESD and Anti-YAG protection are available as front cover accessories to enhance the product flexibility reducing the number of models and simplifying the stock management.

The IP67 and IP65 industrial grade rating and the operating temperature range from 0 to 45 ºC / 32 to 113 ºF guarantee the best quality and robustness in the Manufacturing Industry applications. The Matrix 220 XAI imager offers cost-effective communication options onboard: PROFINET/IO and ETHERNET/IP industrial fieldbus.

Electronics

Automotive

Packaging

Scanner Device only, additional accessories are required.

937900066

Contact us for stock availability

Contact for order requests

937900065

Contact us for stock availability

Contact for order requests

937900064

3 In stock

Contact for order requests

937900063

Limited stock available

Contact for order requests

Required, some fixed scanners have communication cables molded into the housing to connect to the connection box, output cables may still be required. Please refer to topography diagram in Reference manual for more information.

93A050060

7 In stock

Contact for order requests

93A050059

Limited stock available

Contact for order requests

93A050124

6 In stock

Contact for order requests

93A050123

Contact us for stock availability

Contact for order requests

93A050122

Contact us for stock availability

93A050058

Contact us for stock availability

Contact for order requests

Required on all fixed mount scanning unless Quicklink Series connections are used. Please specify additional outputs if required and adapters.

93A301068

Limited stock available

Contact for order requests

93A301067

4 In stock

Contact for order requests

93A301077

Contact us for stock availability

Contact for order requests

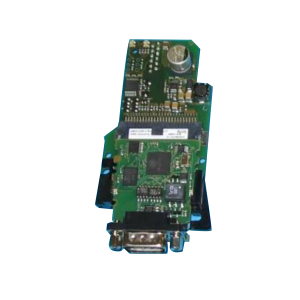

Optional (only required on certain models), only works with CBX500 & CBX800 connection boxes.

93ACC1852

Contact us for stock availability

93ACC1851

Contact us for stock availability

Contact for order requests

93ACC1849

Contact us for stock availability

93ACC1848

Contact us for stock availability

Contact for order requests

93ACC1845

Contact us for stock availability

93ACC1840

Contact us for stock availability

Contact for order requests

93ACC1816

Contact us for stock availability

Contact for order requests

93ACC1815

Contact us for stock availability

93ACC1814

Contact us for stock availability

93ACC1813

Contact us for stock availability

Contact for order requests

93ACC1812

Contact us for stock availability

Contact for order requests

93ACC1811

Contact us for stock availability

Contact for order requests

93ACC1810

Contact us for stock availability

Contact for order requests

93ACC1809

Contact us for stock availability

Contact for order requests

93ACC0113

Contact us for stock availability

Contact for order requests

93ACC1808

Contact us for stock availability

Contact for order requests

Additional Accessory – only required for certain cable sets.

(Optional) WebSentinel Plus is a very advanced monitor and information collector, a supervisory software solution for monitoring operational activities of reading devices through a single web browser-based interface. It collects data from scan points through an Ethernet TCP/IP network, and presents the information flow as visual onscreen information. It also stores this information in a database and, periodically or on demand, produces performance, diagnostic, and tracking reports.

93A101031

Contact us for stock availability

93A101029

Contact us for stock availability

93A101028

Contact us for stock availability

Contact for order requests

93A101027

Contact us for stock availability

Contact for order requests

93A101024

Contact us for stock availability

Optional on request.